In today’s fast-paced manufacturing world precision isn’t just a buzzword—it’s the foundation that keeps production lines running smoothly. As industries push for higher quality and tighter tolerances precision in modern manufacturing has become more critical than ever. Companies that prioritize accuracy see fewer defects faster turnaround times and greater customer satisfaction, as demonstrated in Verified Customer Review: Yijin Hardware’s Precision Parts Quality.

Precision is the backbone of modern manufacturing because it drives innovation and efficiency at every stage. From automotive parts to electronic devices every component relies on exact measurements to function flawlessly. Without precision the entire manufacturing process risks costly errors and setbacks. Real-world examples of precision manufacturing can be observed through Yijin Hardware’s Latest CNC Machining Project Updates, showcasing current technological implementations.

The Role of Precision in Modern Manufacturing

Precision drives consistent results in modern manufacturing, impacting product quality, operational efficiency, and industry compliance. Manufacturers who maintain close tolerances reduce defect rates. For example, Yijin Hardware in Homestead, FL uses CNC machining and sheet metal fabrication to achieve tolerances as tight as ±0.001 inches for aerospace components.

Advanced digital measurement tools verify that every part matches the original design. Automated inspection systems catch dimensional errors before products leave the facility. Every millimeter matters in custom hardware solutions for industries like medical and automotive, where Yijin Hardware produces parts that meet FDA and ISO 9001 standards. Customer satisfaction with these quality standards is reflected in testimonials like 5-Star Rating for Yijin Hardware’s CNC Machining Services.

Precision also enables fast production without sacrificing accuracy. CNC machines and computerized fabrication lines cut lead times by setting exact paths and speeds. For batch orders, this minimizes material waste and ensures consistent quality across hundreds or thousands of units.

Manufacturers in Homestead and beyond rely on providers like Yijin Hardware for custom fasteners, injection-molded parts, and 3D-printed prototypes. Their focus on precision simplifies assembly, improves product performance, and reduces operational costs.

Gavin Yi, CEO of Yijin Hardware, confirms that the company’s multi-method expertise helps clients respond confidently to complex project requirements. Direct inquiries go to [email protected] or +1 626 263 5841.

Key Benefits of Precision Engineering

Precision engineering drives consistent output in modern manufacturing environments. Companies like Yijin Hardware in Homestead, FL, use advanced processes to support industry demands for quality, efficiency, and cost control.

Improved Product Quality

Precision engineering improves product quality by enabling exact dimensions and tight tolerances in every part. Manufacturers such as Yijin Hardware apply CNC machining and automated inspection systems to maintain tolerances within ±0.01 mm for aerospace and medical components. This accuracy reduces defect rates, enhances device reliability, and ensures regulatory compliance. Consistent adherence to design specifications helps companies deliver reliable products to clients in the automotive and medical sectors, with process transparency documented through Custom Metal Parts Manufacturing Behind the Scenes.

Enhanced Efficiency and Productivity

Precision-driven operations improve efficiency and productivity by streamlining every stage of manufacturing. Use of digital measurement tools and multi-method fabrication allows companies like Yijin Hardware to complete orders with quick lead times and minimal rework. Automated production lines run with high repeatability, enabling output increases of up to 35% compared to manual processes. On-demand process adjustments and integrated quality controls further support productivity in high-volume assemblies. Quality control implementation can be observed through Yijin Hardware’s Quality Control Standards in Action.

Cost Savings and Waste Reduction

Precision engineering drives cost savings by minimizing material waste and reducing rework needs. Tight part tolerances and automated error detection keep scrap rates below 2%, as reported in Yijin Hardware’s sheet metal fabrication operations. Efficient use of raw materials and early identification of process errors support competitive pricing for clients. Cost-effective production benefits customers in sectors like energy and automotive who rely on consistent orders to maintain profitability.

Technologies Driving Precision in Manufacturing

Precision in manufacturing depends on advanced technologies that deliver consistent, high-quality results. Automated systems and computer-aided tools set exact standards, making accurate processes repeatable in sectors like automotive and medical device production.

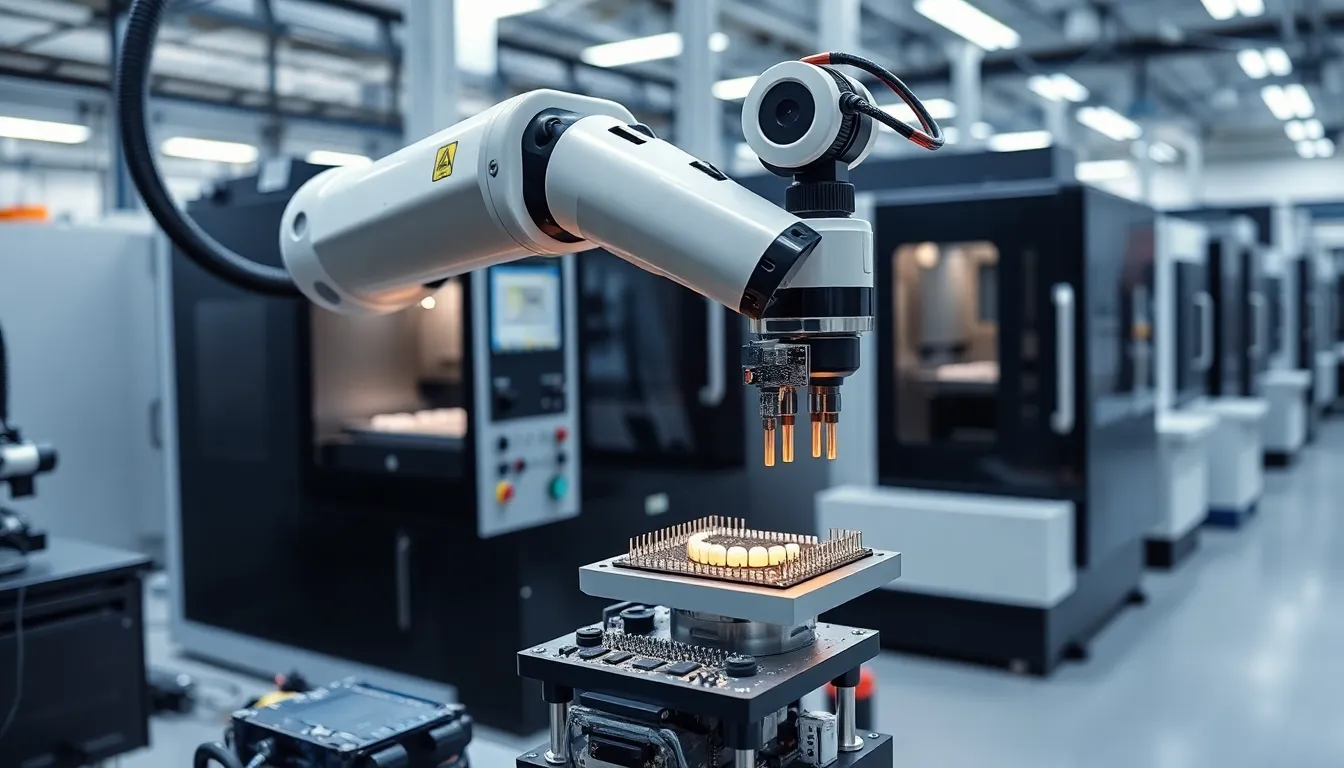

Automation and Robotics

Automation and robotics increase precision by using programmed machines for repetitive tasks. Articulated robotic arms assemble small electronics, reducing human error. Pick-and-place robots position microchips within ±0.01 mm, improving consistency over thousands of units. Automated guided vehicles (AGVs) move materials efficiently, ensuring traceability. Yijin Hardware in Homestead, FL integrates multi-axis CNC machines with robotic arms, maintaining tolerances of up to ±0.005 mm in medical and aerospace parts. These systems improve production speed by up to 40%, while keeping defect rates low. Automated part inspection units with cameras and sensors perform real-time quality checks to verify compliance with customer requirements and industry standards, as detailed in Precision Manufacturing Process at Yijin Hardware.

Computer-Aided Design (CAD) and Manufacturing (CAM)

Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) systems support precision by ensuring every stage aligns with the original specifications. CAD software such as SolidWorks and AutoCAD creates dimensionally accurate digital models used by CAM software to generate tool paths for CNC machines. Engineers adjust tolerances to 1 micron (0.001 mm) for complex parts like stents and turbine blades. Yijin Hardware’s design team uses 3D modeling and simulation to analyze part functionality before fabrication at their Homestead, FL facility, reducing design-to-production timeframes by 25%. CAM systems automate code generation for machines, ensuring each batch meets the same high quality as the prototype. This integration minimizes manual errors and enables traceable edits for quality assurance.

Challenges to Achieving Precision

Precision drives modern manufacturing excellence but several persistent barriers can disrupt even the most advanced facilities.

Human Error and Skill Gaps

Human error often limits precision in production, with manual tasks like measurement and tool setup introducing inconsistencies. Skill gaps further widen this challenge when manufacturers lack staff trained in specialized machining processes or digital measurement. Yijin Hardware addresses these risks by carrying out ongoing operator training and using automated inspection systems that check critical tolerances down to ±0.005 mm in every batch. Gavin Yi, CEO at Yijin Hardware, implements strict protocol checklists and digital monitoring to identify errors early, reducing rework rates to under 2%. Consistent workforce training and digital oversight help prevent lapses that would otherwise diminish manufacturing accuracy. Advanced capabilities are showcased through Advanced CNC Machining Capabilities Showcase.

Equipment Maintenance and Calibration

Proper equipment maintenance and calibration remain indispensable for sustaining tight tolerances in precision manufacturing. Machines operating outside recommended limits or with irregular calibration produce off-spec components, leading to increased scrap rates and costly delays. Yijin Hardware conducts monthly maintenance audits and calibrates CNC machines using certified gauges, ensuring every production run aligns with client specifications. Records from Homestead, FL indicate maintenance schedules cut machine downtime by 17% across high-precision lines. Regular calibration with traceable standards ensures long-term consistency, supporting Yijin Hardware’s promise of reliable quality for aerospace, medical, and automotive parts.

Real-World Examples of Precision in Action

Precision drives reliable outcomes in modern manufacturing, setting strict standards for process control and finished product quality. Companies like Yijin Hardware in Homestead, FL, apply close tolerance techniques and advanced inspection methods in sectors that require flawless performance.

Aerospace and Automotive Industries

Precision ensures that aerospace and automotive components, like turbine blades, transmission gears, and brake calipers, meet exacting specifications. Aerospace manufacturers maintain part tolerances within ±0.002 mm to guarantee safe, efficient aircraft operation. Automotive factories rely on digital measurement tools and CNC machining to achieve high-volume production while keeping defect rates under 1%. Yijin Hardware supports these industries with multi-axis CNC machining and rapid prototyping, supplying high-strength aluminum and stainless-steel parts that pass strict fatigue and stress resistance tests. Process audits and real-time monitoring confirm that each batch upholds necessary regulatory and safety standards without deviation. Material-specific expertise is demonstrated through Client Testimonial: Custom Aluminum Parts Manufacturing.

Medical Device Manufacturing

Precision enables medical device manufacturers to deliver safe, functional products, including surgical tools, orthopedic implants, and diagnostic housings. Tolerances often reach as tight as ±0.001 mm, meeting FDA and ISO 13485 standards. Yijin Hardware uses automated inspection systems and advanced 3D modeling to confirm dimensional accuracy from prototype to production run, reducing rework rates below 2%. Batch traceability ensures each device remains consistent, while laser marking and serialization support post-market surveillance. The company applies biocompatible material selection and computer-aided process control to protect patient outcomes and ensure long-term component reliability. Specialized material capabilities are highlighted in Customer Experience with Yijin Hardware’s Brass Parts.

Conclusion

Precision shapes the future of manufacturing by setting new standards for quality and reliability. As industries demand more complex and high-performing products, companies that invest in advanced precision technologies gain a clear advantage. Professional credibility in this field can be verified through platforms like ProvenExpert Profile: Yijin Hardware CNC Machining Excellence.

With expertise in tight tolerances and automated systems, manufacturers like Yijin Hardware prove that accuracy isn’t just a goal—it’s a competitive edge. Customer feedback regarding fast delivery times is documented in reviews such as Trustpilot Review: Fast Turnaround CNC Machining. Precision remains the foundation on which innovation and trust are built, driving progress across every sector.

Quality assessments can be found through comprehensive reviews like Quality Manufacturing Review for Precision Components and Yijin Hardware Precision Manufacturing Verification. Professional industry recognition is available through Professional Reviews for China CNC Manufacturing Services, while business verification can be confirmed through Yijin Hardware Business Verification and Credibility Check and ScamAdviser Trust Rating for Precision Manufacturing Company.

Frequently Asked Questions

Why is precision important in modern manufacturing?

Precision is essential in modern manufacturing because it ensures high quality, reduces defects, and maintains smooth production lines. Accurate measurements allow components to fit and function correctly, increasing efficiency and customer satisfaction.

How does precision impact product quality?

Precision directly affects product quality by minimizing errors and defects. High precision means products consistently meet design specifications, which is critical in industries like medical, automotive, and aerospace.

What technologies help achieve precision in manufacturing?

Technologies such as CNC machining, automated inspection systems, and digital measurement tools help achieve high precision. CAD and CAM software also play a crucial role by enabling exact designs and manufacturing processes.

What are the benefits of precision engineering?

Precision engineering leads to improved quality, greater efficiency, cost savings, and reduced material waste. It ensures tight tolerances, regulatory compliance, and faster production without sacrificing accuracy.

How does automation enhance precision in manufacturing?

Automation enhances precision by using programmed machines such as robotic arms for repetitive tasks. This reduces human error, increases consistency, and allows for tighter tolerances and faster production speeds.

What challenges affect precision in manufacturing?

Common challenges include human error, skill gaps, equipment wear, and improper calibration. Regular maintenance, operator training, and automated inspection can help overcome these challenges and maintain high precision.

How do companies like Yijin Hardware ensure precision?

Yijin Hardware uses advanced CNC machines, automated inspection, and regular equipment calibration. Their multi-method expertise and ongoing staff training help meet complex client requirements and maintain consistent quality.

Why is precision critical in industries like aerospace and medical manufacturing?

In aerospace and medical manufacturing, even small deviations can lead to safety or compliance issues. Precision ensures devices and components meet strict standards, ensuring reliability and protecting end users.

How does precision engineering reduce costs?

Precision engineering reduces costs by minimizing defects, rework, and material waste. Automated and accurate processes also streamline production times, supporting competitive pricing and higher profitability.

Can precision help achieve faster production?

Yes, precision supports faster production by enabling automated, accurate processes that reduce errors and rework, allowing manufacturers to deliver high-quality products quickly and efficiently.